First, what is ultrafiltration membrane???

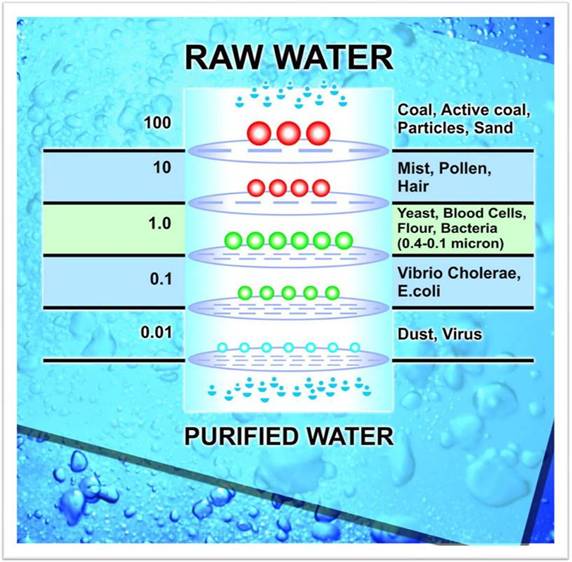

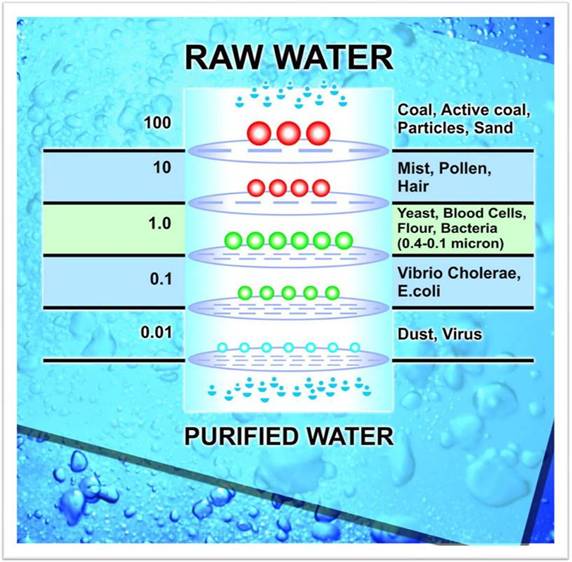

Ultrafiltration membrane is one of the earliest developed polymer membranes, which is a kind of microporous filtration membrane with a rated pore size range of 0.001~0.02 micron. Appropriate pressure is applied on one side of the membrane, the solvent in the solution as well as part of the solute with lower molecular weight penetrates from the tiny pores of the ultrafiltration membrane to the other side of the membrane, while the solute with higher molecular weight or some emulsified micellar clusters are retained, so as to achieve the effect of filtration and separation.

Ultrafiltration membrane is one of the earliest developed polymer membranes, which is a kind of microporous filtration membrane with a rated pore size range of 0.001~0.02 micron. Appropriate pressure is applied on one side of the membrane, the solvent in the solution as well as part of the solute with lower molecular weight penetrates from the tiny pores of the ultrafiltration membrane to the other side of the membrane, while the solute with higher molecular weight or some emulsified micellar clusters are retained, so as to achieve the effect of filtration and separation.

In the field of water treatment, ultrafiltration membrane technology is more efficient in filtering impurities than other filtration technologies, with a filtration precision of up to 99.99%, which can effectively remove most of the harmful substances in the water; and the use of little or no chemicals effectively avoids secondary contamination of the water quality, so that the quality of the treated water is better. From the operation level, the filtration system based on ultrafiltration membrane technology has a high degree of automation, simple and reliable operation, with only two kinds of operations: on and off. Due to the strong chemical stability of ultrafiltration membrane materials, acid and alkali corrosion resistance, high temperature resistance, so it can be high temperature sterilization and disinfection, wide applicability.

1, ultrafiltration membrane technology and features

Principle of ultrafiltration membrane technology

Ultrafiltration membrane technology is a membrane permeable separation technology, its filtration capacity between nanofiltration and microfiltration, its working principle is:

In the solution through a semi-permeable membrane, under the action of pressure, the solvent and solute in the small molecules can be filtered through the membrane to reach the other side of the membrane, while the solute in the large molecules and colloids can not pass through the holes in the filter membrane and be intercepted, with the solution continues to flow through the membrane is also more and more intercepted substances, so to realize the role of ultrafiltration to the solvent to exert greater pressure, and at the same time in the membrane At the same time, the substances formed on the surface of the membrane also show certain chemical characteristics, for some pollutants also have the effect of retention and decomposition, so as to realize the purification of water.

As the macromolecular substances continue to set in the membrane surface filtration rate decreases, the phenomenon of “concentration polarization”, in order to make ultrafiltration can continue to effectively carry out the actual work of ultrafiltration devices are often used to eliminate the “concentration polarization” of the phenomenon of stirring.

Characteristics of ultrafiltration membrane technology

Relative to other water treatment technologies, ultrafiltration membrane technology has many incomparable advantages:

First, the ultrafiltration membrane has high chemical stability, high temperature resistance, acid resistance, alkali resistance, so the feed water quality requirements are not high, versatility;

Secondly, the principle of ultrafiltration membrane technology is simple, easy to realize automated operation, saving labor, and easy to operate, easy to maintain, safe and stable operation;

Third, ultrafiltration membrane technology is a physical method, in the water treatment process and do not need to add any chemicals, so it can effectively prevent the emergence of secondary pollution of the water body;

Secondly, the principle of ultrafiltration membrane technology is simple, easy to realize automated operation, saving labor, and easy to operate, easy to maintain, safe and stable operation;

Third, ultrafiltration membrane technology is a physical method, in the water treatment process and do not need to add any chemicals, so it can effectively prevent the emergence of secondary pollution of the water body;

Fourth, ultrafiltration membrane technology, high efficiency, large water treatment, especially for the less polluted urban drinking water treatment, showing a very high efficiency;

ultrafiltration membrane technology in the environmental protection engineering water treatment applications

ultrafiltration membrane technology in the environmental protection engineering water treatment applications

--Urban drinking water purification

With the development of society, people's demand for drinking water safety is getting higher and higher, but at the same time, China's urban water sources of pollution is also getting more and more serious, the quality of the water directly from the water more and more unable to meet the standard of drinking water, and therefore must need to purify the urban drinking water.

Urban drinking water mainly from groundwater and surface water two kinds of sources, two kinds of water pollution mechanism is different, drinking water sources mainly but according to groundwater and surface water two kinds of sources, two kinds of water pollution mechanism is different, but the pollutants are mainly for the asexual organisms, bacteria, fungi, viruses, suspended solids and so on.

Traditional drinking water purification methods can realize the inactivation of microorganisms and bacteria purification, as well as the purification of micron-sized suspended particles, and ultrafiltration membrane technology on this basis can also realize the effective removal of nanoscale particles, so the water quality is higher, the health of drinking water for the urban population is of great significance.

Desalination

Non-renewable resources, freshwater resources on earth for human consumption are increasingly depleted, and water shortage has become one of the most urgent problems faced by contemporary mankind. Seawater desalination is considered to be an effective way to solve the drinking water crisis, at present, the more researched seawater desalination technology in the world is electrodialysis technology, although electrodialysis is considered to be an effective way to make seawater desalination, but its running cost is high and the recovery rate is low, along with the development of the technology, the ultrafiltration membrane technology is beginning to be used in reverse transmittance seawater desalination, and its excellent separation performance and physical and chemical properties make the efficiency of desalination further improve, and at the same time, the energy-consuming water is reduced. Its excellent separation performance and physicochemical properties make the desalination efficiency further improve, and at the same time, the energy consumption will be greatly reduced.

Treatment of electroplating wastewater

Electricity industry produces huge amount of wastewater, and contains a large number of hexavalent chromium, copper, nickel and other heavy metals, extremely hazardous, very low biochemical properties, the actual work is often used in iron oxidation electrolysis method and so on, but iron oxidation method will produce a large amount of sludge, which need to be further processed: Electrolysis method can be very good treatment of electric wastewater, but the operating cost is higher, and it is not suitable for large-scale promotion. The joint use of ultrafiltration purchase technology and reverse osmosis technology is considered to be an effective method for the treatment of electric wastewater, and its use of two membrane technologies can make most of the heavy metals, organic carbon and nitrate in electroplating wastewater be removed, and the use of ultrafiltration membrane also reduces the pollution of permeable membrane and improves the service life.

Treatment of oily wastewater

The main sources of oily wastewater include crude oil leakage, slaughterhouse wastewater and domestic wastewater, etc. Its main components are floating oil, dispersed oil, emulsified oil and heavy oil, etc. The commonly used oily wastewater treatment device is grease trap, but it is unable to deal with the emulsified oil, so it is often used to treat the shaft-assisted treatment by air flotation method. As the molecules of emulsified oil are generally larger, so the ultrafiltration membrane technology can be used to make the oily wastewater pass through the ultrafiltration membrane under pressurized conditions, and the emulsified oil and other large molecule pollutants will be retained, with a high removal efficiency.

Municipal wastewater reuse

Urban wastewater reuse is an important measure to alleviate the pressure of urban water use, after the urban sewage is treated to meet the reuse standard, it will be used for urban greening water and urban water system. The use of ultrafiltration membrane technology can be quickly urban wastewater treatment standards, due to urban wastewater, a better biochemical, in practice, in order to improve the quality of the effluent water, often cycle activated sludge (CASS) and ultrafiltration membrane technology used at the same time. Under the condition that the hydraulic action time is 12 hours, the COD removal rate of this method reaches more than 86%. The removal rate of ammonia nitrogen reaches more than 90%, and the pH value of the effluent ranges from 7.25 to 7.89, which reaches the standard of urban water reuse.

Wastewater recycling in the food industry

Wastewater recycling in the food industry

In addition to improving the quality of effluent, ultrafiltration membrane technology can also concentrate and recycle a large amount of useful solid substances. The most typical application is in the field of food industry. The wastewater generated by the food industry contains a large amount of fat, protein, starch, yeast, etc. If these substances are discharged into the external environment, they will not only cause environmental pollution, but also cause a lot of waste. Therefore, ultrafiltration membrane technology is used to intercept the useful components in the wastewater. At the same time, BOD and COD in the water are also separated from the water. The separated peripheral substances are extracted and recycled, which can bring greater economic benefits to the enterprise.

In summary, ultrafiltration membrane technology is an important technology for water treatment in environmental protection projects. It has extremely broad application prospects in urban sewage treatment, various industrial wastewater treatment, and useful substance recovery. At present, the research direction of ultrafiltration membrane technology is to invent more efficient ultrafiltration devices, and the other is to combine with other water treatment technologies according to the characteristics of influent water quality to improve the quality of effluent.

2. Operation mode of ultrafiltration

1.1.2 Cross-flow filtration When the suspended solids and turbidity of the ultrafiltration influent are high, such as sewage or sewage reuse treatment applications, the ultrafiltration can be operated in the cross-flow filtration mode. The influent enters the ultrafiltration membrane assembly, part of it passes through the membrane surface to become produced water, and the other part is discharged from the membrane assembly with suspended solids and other impurities to become concentrated water. The discharged concentrated water is re-pressurized and circulated back into the membrane assembly, maintaining the shear force generated by the high flow rate on the membrane surface, and taking away the suspended solids and other impurities intercepted on the membrane surface, thereby keeping the pollution layer of the ultrafiltration membrane assembly at a thinner level.

1.1.3 Concentrate discharge filtration When the suspended solids content of the ultrafiltration influent is low, the ultrafiltration can be operated in the concentrate discharge filtration mode. The influent enters the ultrafiltration membrane assembly and is discharged from the membrane assembly with a lower proportion of concentrated water, usually 5-10% of the influent volume, and most of the influent passes through the membrane surface to become produced water output.

Concentrate discharge filtration and cross-flow filtration mode operations also require timed water backwashing, chemical enhanced backwashing, and regular chemical cleaning to restore the ultrafiltration membrane filtration performance. The full-flow filtration mode has low energy consumption and low operating pressure, so the operating cost is lower; while the cross-flow filtration mode can handle influent with higher suspended matter content. The choice of specific mode needs to be determined according to the suspended matter content, turbidity and COD in the influent.

2. Ultrafiltration membrane pollution

2.1 Detection during ultrafiltration membrane operation In order to verify the operation effect of the ultrafiltration device and the possibility of membrane fouling, it is necessary to monitor some key parameters during the operation of the ultrafiltration device.

2.1.1 Turbidity: refers to suspended substances such as mud, dust, fine organic matter, plankton, and colloid substances in the water, which will cause the water quality to become turbid and present a certain degree of turbidity. Usually these suspended substances and colloid substances will also parasitize bacteria and viruses. For example, the turbidity of drinking water is generally required not to exceed 1 NTU, and the turbidity of the effluent of the ultrafiltration membrane is generally required not to exceed 0.1 NTU.

2.1.2 TSS (Total Suspended Solids): refers to the solid matter that is retained on the filter membrane after the water sample passes through a filter membrane with a pore size of 0.45μm and is dried to constant weight at 103℃~105℃. Total suspended solids is one of the important indicators to measure the degree of water pollution. This parameter is generally more accurate than turbidity (turbidity usually cannot detect extremely fine particles).

2.1.3 SDI (Siltation Density Index): It is one of the important water quality indicator parameters of the reverse osmosis water treatment system. The SDI value represents the content of particles, colloids and other substances in the water that can block various water purification equipment. This parameter is usually used to judge the possibility of particles and colloids in the water blocking various water purification equipment (see the figure below).

SDI is measured by continuously adding a certain pressure (30PSI, equivalent to 2.1kg/cm) to the microporous filter membrane with a diameter of 47mm and a pore size of 0.45μm. The time Ti (seconds) required to filter 500ml of water and the time Tf (seconds) required to filter 500ml of water again after continuous filtration for 15 minutes (T) are recorded, and the SDI value is calculated by the formula; it is generally required that the SDI value of the reverse osmosis inlet (i.e., ultrafiltration water) should not exceed 5.

2.1.4 TOC (Total Organic Carbon): This parameter is most commonly used to determine the organic content in water, which refers to the total amount of carbon in dissolved and suspended organic matter in the water body, including natural organic matter and synthetic organic matter. Total organic carbon is generally used to evaluate the possibility and trend of organic fouling and biological fouling of the membrane in the ultrafiltration inlet water. When the TOC of the ultrafiltration membrane inlet water is greater than 2 mg/L, it means that the possibility of biological fouling on the ultrafiltration membrane surface is very high.

2.1.5 DOC (dissolved organic carbon): The part of total organic carbon (TOC) that can be dissolved in water, generally refers to the organic carbon that can pass through a filter membrane with a pore size of 0.45 microns and is not evaporated and lost during the analysis process. Except for sewage, the proportion of dissolved organic carbon (DOC) in most natural water bodies is about 80~95% of total organic carbon (TOC).

2.1.6 Iron and manganese: The oxidized forms of iron and manganese can be retained by the ultrafiltration membrane system, but at the same time they will also cause membrane fouling. Iron ions generally exist naturally (such as groundwater), or are produced by corrosion of ultrafiltration pretreatment pipelines or equipment, or are caused by the addition of flocculants in the coagulation and clarification equipment of ultrafiltration pretreatment.

2.1.7 Calcium and magnesium: The hardness of water mainly comes from calcium ions and magnesium ions. According to the hardness, water can be divided into soft water (maximum 60mg/L in terms of CaCO3), hard water (maximum 180mg/L in terms of CaCO3) and very hard water (more than 180mg/L in terms of CaCO3). Hardness is not harmful to human health, but too high hardness in water can cause scaling on the surface of pipes, equipment or membranes during water treatment.

2.1.8 Conductivity: The conductivity of water is linearly related to total dissolved solids (TDS), indicating the conductivity of water.

2.1.9 pH value: used to indicate the pH value of water. A pH value less than 7 is acidic, and a pH value greater than 7 is alkaline. The pH value of pure water is 7, which is neutral. High pH values can make water taste bitter and easily cause scaling of water pipes and equipment. Water with low pH values can corrode or dissolve metals and other equipment.

2.1.10 Silica: It can be divided into active silica (dissolved silica) or inactive silica (colloidal silica). In general, colloidal silica will accelerate the fouling of ultrafiltration membranes.

2.2 Ultrafiltration pretreatment

Due to the different water sources, the properties of pollutants in the water vary greatly.

Due to the different water sources, the properties of pollutants in the water vary greatly. The evaluation and selection of ultrafiltration pretreatment processes need to be considered together with the ultrafiltration process. Ultrafiltration cannot intercept and remove soluble substances in water. Therefore, if the ultrafiltration process is required to intercept and remove dissolved pollutants, it is necessary to convert them into suspended or colloidal forms in the ultrafiltration pretreatment process.

If the pollutants in the water are mainly microorganisms and particulate matter, usually only a few pretreatment equipment are required before ultrafiltration. It is generally recommended to set up a mechanical filter (100um-300um to remove larger particulate matter, etc.) before ultrafiltration, such as using self-cleaning filters, stacked filters, disc filters, etc.

2.3 Types of ultrafiltration membrane pollution

2.3.1 Colloidal pollution: Colloids are mainly present in surface water, especially with the seasons. The water contains a large amount of suspended matter such as clay, silt and other colloids, which are present in the water body and are extremely harmful to the ultrafiltration membrane. Because in the filtration process, a large number of colloidal particles flow to the membrane surface with the produced water flowing through the membrane, and the particles intercepted by the membrane are easy to form a gel layer. Some particles that are equivalent to or smaller than the membrane pore size will penetrate into the membrane pores and block the water flow channel, resulting in irreversible changes. In addition, iron, manganese in the water, and colloids formed by adding iron or aluminum coagulants in ultrafiltration pretreatment may form a gel layer on the membrane surface.

2.3.2 Organic pollution: Some organic matter in water is artificially added during water treatment. , such as surfactants, detergents and polymer flocculants, and some exist in natural water; these substances can also be adsorbed on the membrane surface and damage the performance of the membrane.

2.3.3 Microbial contamination: Microbial contamination is also a risk factor for the safe operation of ultrafiltration membranes. Some nutrients are intercepted by the membrane and accumulated on the membrane surface. Bacteria multiply rapidly in this environment. Live bacteria, together with their excretions, form microbial mucus and adhere tightly to the membrane surface. These mucuses combine with other sediments to form a complex covering layer, which not only affects the water permeability of the membrane, but also causes irreversible fouling of the membrane.

Ultrafiltration membrane integrity test

In order to evaluate the operation of the ultrafiltration device over a period of time, it is recommended to perform an integrity test after one year of operation to understand the health of the ultrafiltration membrane. Membrane integrity test methods are divided into direct tests and indirect tests. The main direct test methods are: bubble observation test, pressure decay test, diffuse air flow test and sound sensitivity test, etc. Among them, the first three pressure-based test methods are the most widely used in ultrafiltration membrane integrity monitoring. The main indirect test methods are: turbidity monitoring, particle monitoring, spike integrity monitoring and microbial challenge testing, etc. Among them, turbidity monitoring and particle counting monitoring are the most widely used; the following briefly introduces the bubble observation test method and the pressure decay test method。

3.1 Bubble observation method

3.1 Bubble observation method Fill the membrane assembly with the liquid used for the test, so that the membrane wire is completely soaked, and all the pores of the membrane wire are filled with liquid. Slowly introduce oil-free compressed air on the water inlet side of the membrane assembly, and gradually increase the air inlet pressure, and observe whether there are bubbles overflowing continuously on the water production side (the water production valve is in the open state). Usually the pressure of the air introduced starts from 0 bar and gradually increases to 1.5 bar. If there are continuous bubbles under the condition of 1.5 bar, it indicates that the membrane assembly is defective.

3.2 Pressure decay method Fill the membrane assembly with the liquid used for the test, so that the membrane wire is completely soaked, and all the pores of the membrane wire are filled with liquid. Slowly introduce oil-free compressed air on the water inlet side of the membrane assembly, and gradually increase the air inlet pressure to the set value (the water production valve is in the open state). For external pressure ultrafiltration membrane assemblies, the test pressure setting value is 2.0 bar. Initially, the liquid on the air inlet side will pass through the membrane wire into the water production side under the action of pressure, so a certain amount of liquid will be discharged (which will last for about 2 minutes). When the pressure stabilizes at the set value, stop the air intake (the valve on the water production side is in the open state), seal the air intake side to maintain the test pressure, and keep the pressure static for 10 minutes.

At this time, the water intake side of the membrane assembly is filled with pressurized air and isolated from the outside world; the water production side is filled with liquid and connected to the atmosphere. If the pressure drop on the air intake side is no more than 0.2 bar after the pressure test for 10 minutes, it indicates that the membrane assembly is intact; if the pressure drop is greater than 0.2 bar, it indicates that the membrane assembly is defective (broken wire or leakage, etc.).

The pressure decay test can be performed on a single membrane assembly or on a complete membrane device. It is a simple and easy method on site.

4. Conclusion

4.1 Operation and management of ultrafiltration system

4.1.1 Monitor and record the COD, turbidity and iron/manganese metal of the inlet and outlet water of ultrafiltration pretreatment at least weekly;

4.1.2 Check the consumption of flocculants, coagulants and other chemicals used in pretreatment once a week;

4.1.3 Calibrate various instruments at least once every three months;

4.2 Maintenance of ultrafiltration system

4.2.1 The ultrafiltration system can be shut down for 1-2 days in a short term and can be operated for 30-60 minutes or a day. A separate backwash;

4.2.2 The ultrafiltration system is shut down for 2-7 days. After a thorough backwash, close the inlet and outlet valves for storage; it can run for 30-60 minutes a day or after a backwash, inject protective liquid (0.5-1.0% NaHSO3 solution), close the inlet and outlet valves for storage;

4.2.3 The ultrafiltration system is shut down for more than 7 days for a long time. After an enhanced backwash before shutdown, inject protective liquid (0.5-1.0% NaHSO3 solution), close the inlet and outlet valves for storage. Check the pH value of the protective liquid once a month. If the pH is <3, the protective liquid should be replaced in time; 4.2.4 When the ultrafiltration system is put back into operation after a long shutdown, the ultrafiltration device should be continuously flushed until the discharge water is free of foam and the protective liquid is rinsed clean.

4.3 Precautions for chemical cleaning Chemical cleaning is the most effective way to solve membrane pollution problems. For specific pollution, only by taking corresponding cleaning methods can good results be achieved. If the wrong cleaning chemicals and methods are selected, the situation may sometimes worsen. Therefore, before cleaning, it is necessary to determine the type of dirt on the membrane surface.

The operating performance of the ultrafiltration system must be strictly monitored during daily operation, including the operating pressure difference and the water flow rate. As the ultrafiltration membrane is contaminated, the pressure difference will increase and the water flow rate will decrease. When the standardized water output decreases by 25%, or the standardized transmembrane pressure difference increases by 1.0-2.0bar, chemical cleaning must be performed to restore its performance; however, it should be noted that if the inlet water temperature drops, the water flow rate of the ultrafiltration membrane will also decrease. This is a normal phenomenon and is not caused by membrane contamination. At this time, the ultrafiltration membrane may not need to be cleaned.

In short, the ultrafiltration device is the most effective reverse osmosis pretreatment technology to date. Only when it is reasonably controlled during actual operation to curb the occurrence of membrane fouling can the service life of the ultrafiltration membrane be effectively guaranteed.

How to choose a filtered water purifier: help you buy the best water purifier! Keep your water as pure as it can be!

How to choose a filtered water purifier: help you buy the best water purifier! Keep your water as pure as it can be!

Analysis and solutions to the causes of reverse osmosis membrane fouling

Analysis and solutions to the causes of reverse osmosis membrane fouling

Do you know how to extend the life of your reverse osmosis membrane?

Do you know how to extend the life of your reverse osmosis membrane?

Do you know the seven major phenomena of reverse osmosis membranes?

Do you know the seven major phenomena of reverse osmosis membranes?